Date: September 1, 2016

Author: Paul Cockshott

Were fossil fuels necessary?

Did capitalism itself generate its own technical advances?

Why was energy so vital to the development of capitalism?

Fundamentally it is because by substituting inanimate energy for human muscle, the amount of human time and effort required to make things was reduced. A powered machine replaced the work of human hands and arms. This produced gains in speed, mass and parallelism.

The natural resonant frequency of human limbs sets a maximum number of strokes per minute with which a hammer, saw or needle can be moved. A powered reciprocating mechanism can operate considerably faster. Contrast the number of stitches per second on an electric sewing machine with what can be done with a hand held needle. When the completely rotary motion of a circular saw replaces the back and forth of a hand saw the acceleration is even more marked.

Figure 1: Water powered trip hammers could strike much heavier blows than a person. Modern hydraulic ones (right) are even more powerful. Copyright Wikimedia, license Creative Commons, attribution Rainer Halama.

The weight that can be moved with each stroke or motion can be increased hugely by applying power. Trip hammers turned by water wheels were vastly heavier than any blacksmith could wield, steam hammers and hydraulic presses increased the mass of the hammer by further orders of magnitude. The same magnification applies in a comparison between spades and steam excavators.

Alongside gigantism went parallelism. Instead of one woman turning one spindle, a water wheel or steam engine could turn 100 spindles for each horsepower it produced. A megawatt is 1341 horsepower, so the 90 megawatts or so of installed British water power in 1800 could have turned about 12 million spindles. Of course some of these were powering other machines, but this gives some indication of the equivalent number of workers who would have been needed to produce the same result. But it underestimates the gain in productivity from external power, since the speed of the power spindles is so much faster. Table 1: Installed artificial power in Britain, in MW. Figures computed from Crafts [2004] .

| 1760 | 1800 | 1830 | 1870 | 1907 | |

| Steam | 3.75 | 26 | 123 | 1535 | 7181 |

| Water | 52 | 89.4 | 123 | 186 | 132 |

| Wind | 7 | 11.2 | 14.9 | 7.4 | 3.7 |

| Total | 63 | 126 | 260 | 1713 | 7332 |

A hand spinner could attain a productivity of between 2.5lb and 6lb of yarn per week[6]. A water powered spinning mule, the standard device used in the British textile industry, would have hundreds of spindles per worker and each of these spindles could produce between 25lb and 120lb of yarn per week[8]1. In consequence, each water powered spindle was of the order of 10 or 20 times faster than the human powered one. This means that 90 megawatts of water power, devoted to spinning would produce more like the output of 200 million hand spinners. Table 2: Average output of thermal energy equivalent of UK coal mines assuming 25GJ per ton, from figures in Pollard [1980] and from 1873 from Historical Coal Data: Coal Production, 1853 to 2014, UK Dept of Energy and Climate Change.

| years | MW themal |

| 1760-1765 | 4122 |

| 1800-1805 | 11019 |

| 1830-1835 | 25367 |

| 1873-1882 | 111219 |

| 1903-1912 | 204565 |

Capitalist production first took root using the water power technologies available from antiquity, its novelty in this respect was not the power source but the scale on which it was used and its application to highly parallel machinery. The real novelty, steam power, was at first relatively specialised in its application – used exclusively for pumping water, particularly from mines. It was not until the 1830s that steam power overtook water in installed capacity in Britain, even later in the USA. It has been suggested[9] that the reason steam eventually replaced water in the cotton industry was more a matter of class conflict than technical rationality. Water mills were in isolated rural spots where it was easier for the mill workers to organise strikes than in big cities with their abundant potential blacklegs among the unemployed. Steam power enabled masters to move from where labour was scarce and strong to where it was abundant and weak.

Could capitalism have developed differently, in a way which did not rely on fossil fuel?

Was it just a contingent accident that Faraday’s dynamo and electric motor was invented decades after Watt’s engine?

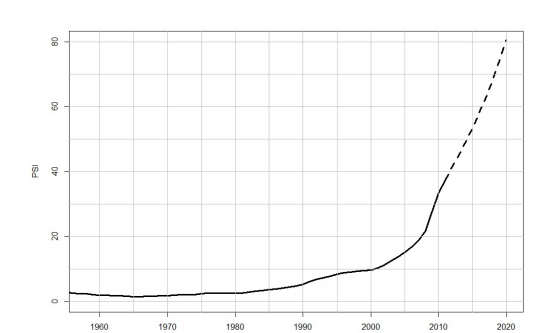

Figure 2: Growth of different forms of energy use during the development of British capitalism. From Tables 1,2. Given the log scale of the Y axis, a straight line represents an exponential growth rate.

Had electro-magnetism been investigated earlier, power could have been transmitted from fast flowing rivers to power factories in cities, thus giving the masters the edge over their workers that steam actually provided. This transformation though, had to await Edison, Tesla and Kelvin in the late 19th century. But even then water power would not have been sufficient to rival steam. In the year 2000 the installed hydro power of the UK was 1400 MW, which is less than the installed steam power was in 1870, and only about a quarter of the total installed power of all types by the end of the 19th century.

We speculated above about a counter-factual situation where Faraday’s generator had been invented before Watt’s engine. There might be conceivable circumstances in which electro-magnetism was developed before steam power, but there are real logical dependencies existing between scientific and technological advances. Heilbroner [1967] argues that it is just this set of dependencies that lie behind Marx’s insistence on the primacy of the productive forces in giving direction to economic and historical development. Knowledge is cumulative. You need prior knowledge of one technology before you can think of improving it. Without the Newcomen engine as a starting point Watt would not have hit on his separate condenser. The possibility of him thinking that it would be worth using a separate condenser, though, depended on him having a prior concept that heat was a quantifiable ‘substance’ that could be saved by not repeatedly cooling the cylinder the way Necomen did. That in turn was only possible because of Watt’s scientific training in Black’s laboratory in Glasgow University[1] – then the leading center for thermodynamic research.

Newcomen and Savery’s pioneering engines in turn depended on the prior disemination of the work of Torricelli on atmospheric pressure, since these devices were, in the language of the day `atmospheric engines’. The power stroke of the engine was driven by atmospheric pressure. The fact that improvements to machines often came not from professional scientists but from technicians like Watt and Cugnot should not be taken to indicate either that the technicians were ignorant of the underlying scientific principles of the machines, or that the discoveries were not dependent on these principles. For example the conversion of rectilinear motion into rotary motion was a considerable engineering problem.2 This was solved by cranks or planetary gears, but that left another problem. With a beam engine you had to combine vertical motion of the piston rod, with rocking motion of the beam which would tend to bend and unseat the piston rod. Watt solved this with his parallelogram linkage[7,[4]. The ability to come up with this requires at least a deep grasp of classical geometry and probably also of Cartesian techniques[3] in order to prove its validity. Something which, when we see it in a museum now, looks literally clunky and crude, actually involved maths which would severely tax most contemporary students.

Figure 3: The conversion of the straight line motion of the piston rod into the rocking motion of the beam was a difficult geometry problem solved by Watt’s parallelogram linkage. Solving the problem requires a good level of geometric education.

A condition therefore of capitalist civilisation, and the technical advances on which it depends, has been the continuing development of science, and the educational and research base on which science relies. These are not something generated internally by capitalist enterprise. They depended initially on royal and later republican state patronage which well preceded the growth of actual capitalist machine industry. Russo et al. [2013] to what extend the science of the 17th and 18th century still rested on royally funded research of the Hellenistic period in Syracuse or Alexandria. From the 17th century royal patronage of research resumed and the universities in Europe became centres of science rather than just religion.

Scientific knowledge, once published, is not property. There is no profit to be made from it, so it has in the main to be produced by social rather than private research. However great the incentive for capitalists to innovate may have been, the mere existence of commodity relations and wage labour would not have been sufficient to generate the capitalist mode of production, contra the implications of Brenner and Wood. Innovations driven just by trial and error, without theory are slow and limited. They only become rapid when coupled with socially produced and accumulated, non-commodified, theory.

References

[1] Donald Stephen Lowell Cardwell. From Watt to Clausius: The rise of thermodynamics in the early industrial age. Cornell University Press, 1971. [2] Nicholas Crafts. Steam as a general purpose technology: a growth accounting perspective. The Economic Journal, 114 (495): 338-351, 2004.

[3] David Dennis. Rene Descartes’ curve-drawing devices: Experiments in the relations between mechanical motion and symbolic language. Mathematics Magazine, 70 (3): 163-174, 1997. ISSN 0025570X, 19300980. URLhttp://www.jstor.org/stable/2691256.

[4] Eugene S Ferguson. Kinematics of Mechanisms from the Time of Watt, volume 27. Smithsonian Institution, 1962.

[5] Robert L Heilbroner. Do machines make history? Technology and culture, 8 (3): 335-345, 1967.

[6] Jane Humphries, Benjamin Schneider, et al. Spinning the industrial revolution. Technical report, Economics Group, Nuffield College, University of Oxford, 2016.

[7] Teunis Koetsier. A contribution to the history of kinematics—i. Mechanism and Machine Theory, 18 (1): 37-42, 1983.

[8] Timothy Leunig. A British industrial success: productivity in the Lancashire and new England cotton spinning industries a century ago. Economic History Review, pages 90-117, 2003.

[9] Andreas Malm. The origins of fossil capital: from water to steam in the British cotton industry. Historical Materialism, 21 (1): 15-68, 2013.

[10] Sidney Pollard. A new estimate of British coal production, 1750-1850. The Economic History Review, 33 (2): 212-235, 1980.

[11] Lucio Russo et al. The forgotten revolution: how science was born in 300 BC and why it had to be reborn. Springer Science & Business Media, 2013.

Footnotes:

1Finer yarns weigh less so productivity in lbs is lower.

2 The initial solution to generating rotary motion from steam was to use a steam engine to pump water up which was then used to turn a water wheel[4].