Date: April 18, 2017

Author: Paul Cockshott

n the social production of their existence, men inevitably enter into definite relations, which are independent of their will, namely relations of production appropriate to a given stage in the development of their material forces of production. The totality of these relations of production constitutes the economic structure of society, the real foundation, on which arises a legal and political superstructure and to which correspond definite forms of social consciousness. The mode of production of material life conditions the general process of social, political and intellectual life. It is not the consciousness of men that determines their existence, but their social existence that determines their consciousness. At a certain stage of development, the material productive forces of society come into conflict with the existing relations of production or this merely expresses the same thing in legal terms with the property relations within the framework of which they have operated hitherto. From forms of development of the productive forces these relations turn into their fetters. Then begins an era of social revolution. The changes in the economic foundation lead sooner or later to the transformation of the whole immense superstructure. (Marx et al. [1978],Preface)

What distinguishes a utopian approach to social transformation from a materialist one is that the latter must start with the real contradictions that exist between technological imperatives and the social forms that currently exist. These specify not a future that might be desired, but what may be required.

One has therefore to start with technology complexes and demographics since all social formations combine a particular set of technologies with a particular density of human population. Only some technology complexes are compatible with a given population density. Our current population could not survive on the basis of pastoralism, so much is obvious. But nor can the present population long survive on the basis of an extractive fossil fuel economy.

Contemporary capitalism is heavily dependent on fossil fuels. Almost 90% of world primary energy comes from these sources and the percentage coming from nuclear and renewable sources has if anything tended to fall slightly in recent years. Industry and commerce use about 60% of all primary energy, transport and residential use around 20% each.

The current mature alternatives to fossil fuels are nuclear energy and hydro power. The latter obviously has severe geographical limitations, the limitations to the use of nuclear power are on the one hand political opposition and on the other the fact that only a small number of countries and firms have the ability to commission nuclear plant. In terms of cost it is already competitive with coal power for electricity1.

The the two rapidly maturing alternative energy sources are solar and wind power. Prices of both of these have been falling rapidly and in the US are already competitive with coal for electricity generation when measured as levelized costs. Obviously both of these depend for their yield on the local wind and sunshine, and so will vary in yield from place to place.

Although Van Vuuren et al. [2011] lay great emphasis on carbon capture

and storage as a mechanism that will allow green house gas emission targets to be met, this is one of the least developed techniques so far. Although there is experience of injecting CO2 into oil reservoirs for enhanced recovery, there is as yet little practical experience in operating full scale coal fired power stations far from oil reservoirs, extracting the CO2, and then piping it to appropriate injection sites. The components are plausible, but the working experience that for example nuclear power has, is absent.

There are clearly hazards associated with subsequent escape of the carbon dioxide from subteranean reservoirs, as shown by the Lake Nyos disaster[3] were 1700 people were killed by a sudden escape of the gas.

However given the good progress being made in other areas it seems plausible that, at least for electricity generation, a combination of nuclear, solar and wind power could replace a large part of current dependence on coal for electricity generation.

Marx claimed that the stage of development of technology is what ultimately determines the bounds on social relations. He believed that communism was the likely future of industrial society and that coal powered steam engines were the foundation of capitalist economy. Is there anything about the transition anything about the transition to a post fossil fuel economy that would favour communism over capitalism?

The USSR depended heavily on large scale integrated production both of energy and other products. The economic regression which followed the

establishment of capitalism made it clear that capitalist property relations were incapable of sustaining this form of the productive forces. The one industry that did relatively well in the new capitalist Russia was fossil fuel extraction.

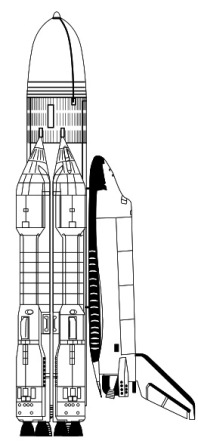

Figure 1: The Soviet Energiya launcher that was intended to put up

orbiting solar power plants. The Buran shuttle is shown attached.

Figure 2: Model of the ITER reactor. Note the human figure for scale. Photo by Stephan Mosel released under Creative Commons.

The USSR did have long term plans for non-fossil energy sources : nuclear, thermonuclear and orbiting solar power stations. All of these are post capitalist forms of energy production in the sense that their development has depended on socialist economy in the East, or in the West on state sponsored development: AEC in the US or the AEA in the UK for nuclear power.

Thermonuclear power research has been overwhelmingly state funded, and the most promising reactor design the Tokamak, was invented in the USSR and forms the basis for the international ITER experimental power reactor[2]. Orbiting solar power stations[8] were a futuristic technology much talked about in the 1970s and 80s. They would overcome the limitations of day and night and bad weather by being bathed in permanent sunlight, and would beam energy to Earth as microwaves. The ultimate Soviet space launcher, Energiya[9], was seen as the tool to build such orbiting stations.

So we could hypothesise that the energetic basis of communist economy would be orbiting solar power stations and huge tokamaks able to supply essentially limitless energy from the deuterium in sea water. This is a pair of technologies that private capital has been unable to develop because of the huge initial investment over many decades before any possible profit could be returned. It would moreover, be a highly capital intensive path and high capital intensity is associated with low profitability, which deters private firms.

The scale of development costs associated with thermonuclear power are so large that they are beyond even what individual nations can afford. The only practical project to build a thermonuclear reactor ITER is being constructed by a consortium of 35 states. ITER was started at the initiative of the USSR at the Geneva Superpower Summit in November 1985. Design work took from 1988 to 2001. In 2005 it was agreed that the site of the reactor would be in France. In 2010 construction started near Aix-en-Provence.

It will be the largest and most complex machine ever constructed. The first plasma is scheduled to be generated in 2025 but it is not anticipated to use actual deuterium/tritium plasma to generate useful power until 2035. The whole project will thus have taken 50 years to yield power. But prior to ITER being formed there had already been a 35 year history of development of the technology since Sakharov and Tamm initially proposed the design in 1950.

The development of thermonuclear plasma reactors is something that private capitalism could not have done. It required foresight based on an appreciation of future human needs that only public bodies, indeed a world public body, could undertake.

Solar and wind power, can in contrast be developed piecemeal with relatively modest capital costs. A such, private firms are quite willing to invest in them, given modest initial government incentives. We do not know yet whether these lower tech approaches to alternative energy will be enough to power future civilisation. If they are enough then – other than international political sanctions restricting fossil fuels – there will be nothing in the energy base that militates against the perpetuation of private ownership. If it turns out that the supply of energy from wind and sun is too intermittent, too dependent on the seasons, too deficient at night, then fusion power will be the most plausible way of providing base load power. If energy storage technologies, either batteries, pumped storage, compressed air storage of even flywheel storage develop fast enough, fusion may not be needed.

This possibility give rise to fantasies about self sufficiency and a society of people who are economically self sufficient, living off-grid. The idea breaks down as soon as it is examined in detail. Solar power only brings an element of self sufficiency to those with enough capital to buy the panels, and enough roof area or free land to install it on. It is not an option for urban dwellers in rented flats or for those who can not afford the initial capital.

Whilst owners of houses with big roofs will be able to reduce their electricity purchases, electric grids will still be needed for industry, telecoms, offices, electric railways etc.

But electical power generation is only part of the emissions problem.

Carbon dioxide is generated by transport and by materials processing.

Materials

Industrial society is heavily dependent on materials whose production either uses fossil fuel, or unavoidably emits carbon dioxide. In the 19th century industrial buildings and housing in industrialised nations were largely built from brick. Brick production involved the mixing of clays with ground coal which were then dried and sintered in kilns, with the coal in the mixture providing a large part of the fuel.

From the 20th century concrete became the main building material. But this too involves a lot of energy in its construction. Concrete is a mixture of sand, stones and cement powder. Cement powder is the biggest energy consumer here. The process involves heating limestone to disassociate the CaCO3 it contains to produce CaO+CO2.

This obviously involves a direct release of carbon dioxide. The process requires between 4GJ/ton and 7GJ/ton of energy[21]. This energy is currently supplied by fossil fuels with of the order of 5% of world industrial energy use going on this process. Worrell et al. [2001] estimated that in 1994 around 5% of total carbon dioxide emissions world wide came from cement production. For China something between 7% and 9% of all emissions are from cement making[14].

It is in principle possible to produce cement without carbon dioxide by a combination of solar heating to melt limestone and then electrolysis by the STEP process[13].

By choice of temperature one can obtain the electrolytic transformation CaCO3→ CaO+C+O2 with elemental carbon and oxygen being released. Assuming that the carbon produced was buried, the overall process would be carbon neutral.2

If operated in a strictly carbon neutral fashion the cost of cement produced this way would be two to three times as great as with current methods.

Steel has been the fundamental metal of industrial society, used in making machinery, ships, bridges, cars and in the construction industry. Steel production comes from two processes today, the basic oxygen process, and the electric arc process.

The basic oxygen process refines pig iron produced in blast furnaces into structural steel, though a portion of the feedstock is recycled scrap steel. Electric arc furnaces work entirely with recycled scrap. In the USA around 70% of all steel output is from recycled sources. The remaining 30% comes from the processing or iron ore. The iron oxide in the ore, is reduced to metalic iron using carbon, currently in the form of coke, though charcoal was used in the past. As such the process inevitably emits carbon dioxide, both because the coke provides the fuel to heat the furnace, and because carbon monoxide produced by burning the coke is the reducing agent.

If we assume that the world will require drastic reductions in CO2

emissions, this implies :

- That the steel industry will have to become overwhelmingly one based on recycling, supplemented with only such small amounts of basic steel

as can be produced from charcoal.

- That other metals, most likely aluminimum, will have to substitute for steel in many uses. Aluminium is produced by an entirely electrolytic process, with a relatively small carbon dioxide emission from the erosion of the

carbon electrodes.

Per ton, in 2017, aluminum cost about 5 times as much as steel. It is also weaker than steel so aluminium structural members have to be thicker than the corresponding steel ones. But given its lower density these effects partially cancel out, and the corresponding aluminium part will weigh only about 60% of the steel part. Overall then the use of aluminium instead of steel is about three times as expensive.

So it is likely that the two fundamental construction materials of industrial civilisation, concrete and steel will have to be replaced by alternatives that

are around 3 times as expensive. Cheap concrete has been the foundation of world urbanisation[5], and cheap steel the foundation of mechanisation.

Stone, of course, will remain available as a low carbon building material when

carbon emissions restrict brick and concrete. Smout [1986] attributes the greater overcrowding and worse slum housing conditions in indutrial Scotland to the statutory requirement, up to the 1930s, to use expensive stone in residential accomodation in Scotland where cheap brick could be used in England.

Now, the old stone tenements of Glasgow are appreciated for their aesthetics, in comparison to the brick and concrete housing that went up in the 1950s. But if the billions of new urban dwellers across the world will have to depend on the building of

stone housing, then over-crowding will persist much longer than would be the case were brick and concrete to be still available. Overcrowding itself brings exploitative landlords; reinforces the dominance of the propertied classes. On the other hand, once population growth slows down, the durability of stone construction is an advantage. Over time, with a static population, relatively high standards of housing could be achieved using stone. In the shorter term it may be necessary for mass produced

aluminium units to stand in where 20th century urbanisation used poured concrete flats.

Transport

As Smil [2010] says, the two engines of globalisation are the high bypass turbine and the high compression diesel. The one powers aircraft, the other: ships, trains, lorries and buses. MAN and Wärtsilä drive the vast ships linking Asia, Europe and America. Diesel trains carry more than half of America’s goods. Turbines power all air freight. All run on oil. Without oil, most world transport stops.

Oil is not going to run out or be banned overnight, but over a few decades either due to resource exhaustion or international restrictions of fossil fuel use, it will become progressively less available. How then is a transport system, and behind that, a whole global capitalist division of labour going to respond?

Looking first at shipping, it is clear that costs will rise. Today we have diesel powered steel ships. At the end of this century what will ships be built of and powered by?

Before steel ships we had wooden ones, and sail power hung on into the early 20th century, so international trade would still be possible by a reversion to earlier technologies. But this would mean both a severe reduction in trade volume and a rise in carrying costs. Vessels of modern size can not be built of wood. Wooden construction implies ships of at most a couple of thousand tons, about a hundredth of the size of the largest contemporary container ships and a tenth the size of the most common bulk carrier. Costs would be much higher because of the large crews needed to handle sails. Figure 3: The Flettner rotor ship. This was developed in the 1920s as an improved form of sail which relies on the perpendicular force generated by the wind on a spinning cylinder. The original ship is on the left with the modern experimental Eship1 on the right.

But there are obvious alternatives. Aluminium has been extensively used in warship construction, and could be used for merchant shipping were owners forced to pay the higher contruction cost.

But nobody has yet built large aluminium ships. The largest have been around 100 metres whereas current freighters run up to four times that length. They have been plauged by corrosion problems. As a highly electo-positive metal, any contact with other metals like bronze or steel sets up a battery on contact with water. The consequence is electrolytic corrosion which eats away at the aluminium. In principle this can be avoided by using only aluminium in the hull. Designs have existed for bulk cargo ships of this type for decades, but have been uneconomic[1]. Overall, an over decades, though there seems little doubt that the technology of building such ships can be mastered. Propulsion is the bigger problem.

Batteries and solar power are ruled out. Batteries, which have long been used in submarines, do not last long enough for ocean voyages, and solar power provides too little energy for a large heavy vessel. Wind remains the most likely alterntive. Designs do exist for cargo ships with conventional masts and sails, but the crew required to handle sails, even with some form of power assist is likely to be more than would be needed for a motor vessel.

A promising alternative is the Flettner rotor.3 This relies on the fact that the wind will exert a perpendicular force on a spinning cylinder. It requires a modest power to rotate the cylinder but, by harnessing the wind, yields much more propulsive power than is put in. Such ships do not need big crews. A couple of cargo ships using this were built in the 1920s, but at that time they proved uneconomic in comparison to diesel. Given that diesel ships have improved a lot since then, they remain uneconomic in the absence of controls on the use of fossil fuels.4

Another possibility is that nuclear energy, long used in warships, might be applied to cargo vessels. There is no doubt that it works, and can drive ships very fast. But there is a big difference between operating it in an environment where cost is no object and you have highly trained crews, and using it in a commercial ship. Of the four experimental atomic cargo ships, Savanah(US), Otto Hahn(German), Mutsu(Japanese) and Sevmorput(Soviet) only the last was a sucess. Cost, reliability and safety considerations have prevented a general uptake of the technology.

So the conclusion to take from this is that the end of the fossil fuel era is likely to lead to a significant increase in shipping costs. They will cost more to build, more to operate, and probably be slower.

This will tend to substantially undermine the current model of globalisation. Higher shipping costs will favour local producers compared to global ones, and land links rather than sea links.

Rail freight is still heavily dependent on diesel in many countries, but electric railways are an old and well tried technology. It is expensive to put in the wires and to buy new locomotives, but running costs subsequently are similar.

Even with the current structure of electricity generation electric trains release less carbon than diesel[7]. As the electricity generation system moves towards renewables and nuclear, this advantage will be come more pronounced. Electrification tends to be high in countries like China where the railways are state

owned and planned and low in countries like the USA where the infrastructure is private.

China’s rail transport volume is one of the highest in the world, having a 93 000 kilometer-long network of which 46 000 km is electrified (Ministry of Railway, China, 2012). The rate of electrification increased gradually: in 1975 it was only 5%, by now it is about 40% as a result of a conscious central planning. (Juhász et al. [2013])

In contrast, only 1% of the US network is electrified. We discussed earlier how, in capitalist economies, high capital intensive industries have a low rate of profit, which discourages investment in them. The contrast between the US and Chinese railways is a particularly stark example of this. The electrification of the railways in large countries like the US is technically feasible as China shows, but it is held back by private ownership. Thus the need to convert to electric trains will tend to favour the replacement of private with public railways.

The percentage of freight carried by train may well rise, because in the absence of of diesel engined lorries, long distance trucking is likely to be unviable. The best electric heavy lorries have a range of only 100km and take several hours to charge. The goods transport system is likely to have electric trucks being used only for final delivery within cities5

For urban transport, electric cars with lithium batteries are certainly a viable replacement for fossil fuel ones. There are questions associated with the long term availability of lithium for the batteries[12]. If the whole world were to attain the current European levels of car ownership, and these all used lithium batteries, it is questionable whether world lithium resources are sufficient, but that is a relatively extreme projection of future use. Gaines et al. [2009] on more modest projections of future car use, conclude that lithium resources are unlikely to be a big constraint.

Lithium is very geographicaly concentrated with the top 4 producing countries having 90% of world reserves. In the event of it being used in all cars, these countries would be in a position to gain rent revenues analogous to the leading oil producers today. On the whole though, these are likely to be smaller than the oil rents in the current world economy, because a) lithium can be recycled, b) unlike oil it will not be a primary energy source.

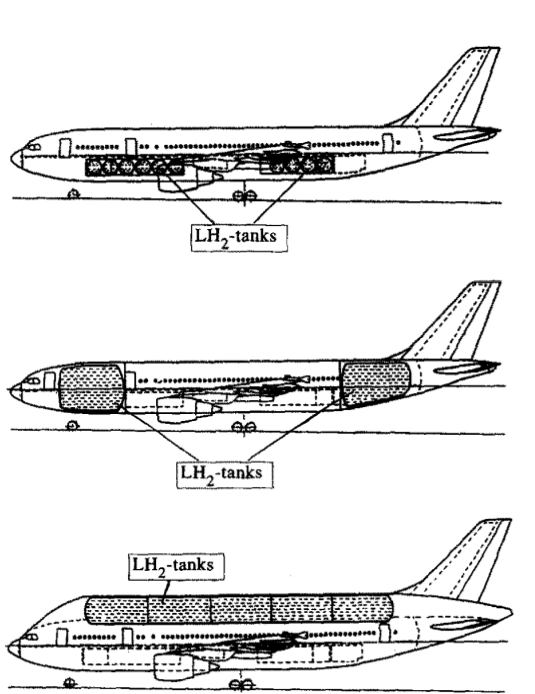

There are no serious engineering problems with converting the aviation industry to

use non fossil fuels. Liquid hydrogen is a viable alternative fuel[11,[4]. It

has a much better energy to weight ratio than existing fuels. Its main drawback is that it is much less dense, meaning that a substantial part of the fuselage volume would have to be given over to fuel tanks. Designs exist for modified Airbus and Boeing jumbo[17] jets powered by it. The Boing design had the upper deck extended the length of the fuselage and entirely filled with liquid hydrogen tanks. In 1988 Tupolev actually built a modified Tu155 that flew on hydrogen[16], the back part of the passenger cabin having to be occupied by the fuel tank.

Figure 4: Airbus design study for hydrogen fuel, from Contreras et al. [1997]

Figure 5: Tu155 modified for hydrogen use in 1988. Note that much of the passenger space is sacrificed. This was fitted with only one hydrogen engine, if all were using hydrogen then the tank would have been bigger.

Although the conversion is possible, it will come at the cost of more expensive flights. Because the fuel is so bulky, the aircraft will be able to carry fewer passengers than a conventional one of the same size. The fuel is also more expensive. Although photo voltaic electricity is begining to rival fossil fuel electricity in lifetime costs, this does not imply that hydrogen produced by electrolysis from solar power is as cheap as kerosene.

Producing electricity from oil proceeds thus:

a) oil(40% efficient)→ electricity

Producing hydrogen by electolysis starting with oil fuel progresses thus:

b) oil(40% efficient)→ electricity (70% efficient)→ hydrogen

Because of the thermodynamic loss in electrolysis. If we substitute this with photovoltaic we have

c) photovoltaic electricity (70% efficient)→ hydrogen

The hydrogen or kerosene aviation fuel then has to be turned into motive power

d) aviation fuel (40% efficient)→ motive power for flights

Suppose photovoltaic electricity costs the same as process a. That means that photovoltaic electricity is of the same cost as flight motive power in process (d) where the aviation fuel is kerosene. But if we have to generate hydrogen and then burn it in a turbine, the overall subsequent efficiency is 70% × 40% = 28%.

So even if photovoltaic electricity is as cheap as fossil fuel electricity, as a source of aviation fuel it will still be more than three times as expensive as kerosene.

Lower passenger capacity and lower thermodynamic efficiency mean that cost per passenger mile will rise substantially.

Overall then we have a series of changes which adversely affect transport, and which, taken together undermine the current basis of globalisation. They shift costs to favour more local production and will make the outsourcing of industry to low labour cost

areas somewhat less viable.

If we combine this with the demographic changes which are going to slow the expansion of the world labour force, then one of the main factors which, this last half century, has worked to undermine the position of labour relative to capital will stop working.

References

[1]

Charles J Altenburg.

Design Considerations for aluminium hull structures.

Ship Structure Committee US Coast Guard, 1971.

[2]Englen A Azizov.

Tokamaks: from a d sakharov to the present (the 60-year history of

tokamaks).

Physics-Uspekhi, 55 (2): 190, 2012.

[3]Peter J Baxter, M Kapila, and D Mfonfu.

Lake Nyos disaster, Cameroon, 1986: the medical effects of large

scale emission of carbon dioxide?

BMJ, 298 (6685): 1437-1441, 1989.

[4]A Contreras, S Yigit, K Özay, and TN Veziroglu.

Hydrogen as aviation fuel: a comparison with hydrocarbon fuels.

International Journal of Hydrogen Energy, 22

(10-11): 1053-1060, 1997.

[5]David Edgerton.

Shock of the old: Technology and global history since 1900.

Profile books, 2011.

[6]Linda Gaines, Paul Nelson, et al.

Lithium-ion batteries: possible materials issues.

In 13th international battery materials recycling seminar and

exhibit, Broward County Convention Center, Fort Lauderdale, Florida,

page 16, 2009.

[7]Moshe Givoni, Christian Brand, and Paul Watkiss.

Are railways climate friendly?

Built environment, 35 (1): 70-86, 2009.

[8]Peter E Glaser, Owen E Maynard, JJR Mackovciak, and EI Ralph.

Feasibility study of a satellite solar power station.

Technical report, NASA, 1974.

[9]Bart Hendrickx and Bert Vis.

Energiya-Buran: the Soviet space shuttle.

Springer Science & Business Media, 2007.

[10]Mattias Juhász, Tibor Princz-Jakovics, and Tünde Vörös.

What are the real effects of rail electrification in hungary?

In European Transport Conference 2013, 2013.

[11]C Koroneos, A Dompros, G Roumbas, and N Moussiopoulos.

Advantages of the use of hydrogen fuel as compared to kerosene.

Resources, Conservation and Recycling, 44

(2): 99-113, 2005.

[12]Duncan Kushnir and Björn A Sandén.

The time dimension and lithium resource constraints for electric

vehicles.

Resources Policy, 37 (1): 93-103, 2012.

[13]Stuart Licht, Hongjun Wu, Chaminda Hettige, Baohui Wang, Joseph Asercion, Jason

Lau, and Jessica Stuart.

STEP cement: solar thermal electrochemical production of CaO without

CO 2 emission.

Chemical Communications, 48 (48):

6019-6021, 2012.

[14]Zhu Liu, Dabo Guan, Wei Wei, Steven J Davis, Philippe Ciais, Jin Bai, Shushi

Peng, Qiang Zhang, Klaus Hubacek, Gregg Marland, et al.

Reduced carbon emission estimates from fossil fuel combustion and

cement production in China.

Nature, 524 (7565): 335-338, 2015.

[15]Karl Marx, Salomea W Ryazanskaya, and Maurice Dobb.

A contribution to the critique of political economy.

Progress Publishers, 1978.

[16]Hans W Pohl and Valentin V Malychev.

Hydrogen in future civil aviation.

International journal of hydrogen energy, 22

(10-11): 1061-1069, 1997.

[17]Robert O Price.

Liquid hydrogen—an alternative aviation fuel?

International journal of hydrogen energy, 16

(8): 557-562, 1991.

[18]Vaclav Smil.

Two prime movers of globalization: the history and impact of

diesel engines and gas turbines.

Mit Press, 2010.

[19]T Christopher Smout.

A century of the Scottish people, 1830-1950.

Collins London, 1986.

[20]Detlef P Van Vuuren, Elke Stehfest, Michel GJ den Elzen, Tom Kram, Jasper van

Vliet, Sebastiaan Deetman, Morna Isaac, Kees Klein Goldewijk, Andries Hof,

Angelica Mendoza Beltran, et al.

Rcp2. 6: exploring the possibility to keep global mean temperature

increase below 2 c.

Climatic Change, 109 (1-2): 95-116, 2011.

[21]Ernst Worrell, Lynn Price, Nathan Martin, Chris Hendriks, and Leticia Ozawa

Meida.

Carbon dioxide emissions from the global cement industry 1.

Annual Review of Energy and the Environment, 26

(1): 303-329, 2001.

Footnotes:

1Data from US Energy Information Administration, Annual Energy Outlook Report 2015.

2 Licht et al. [2012] claim that their proposed STEP process would actually be cheaper than the current method of cement production. But their costings depend on operating the process at a higher temperature at which the outputs would be CO and O2 rather than elemental carbon and oxygen. They then propose to sell the carbon monoxide as a feedstock for plastic production. But this process would not be carbon neutral, as part of the plastics would eventually end up being burned and entering the air.

3I recall my grandfather describing to me the sight of one of these ships in the

20s. At the time I could not understand how it could work.

4Restrictions on fosil fuel for ships may first come as bans on the use of high sulfur oil. The threat of this has alone been enough to spur the revived experimental work on wind power.

5 This is similar to the model of delivery that existed in the UK in the period immediately after nationalisation of the railways and road transport in 1948. Railways for long distances, small trucks for

final delivery.